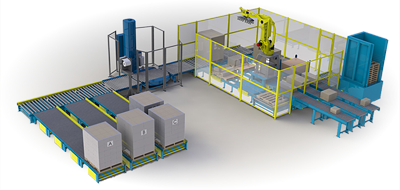

Automation of production - is the main direction of modern technological progress and is a base of industrial sector evolution on a global scale. To improve competitiveness level industrial companies must use specialized equipment for automation of industrial processes.

Automation - is an important process that helps to improve the quality of manufactured products, to raise performance, to improve saving of production resources without deterioration of product quality and to balance energy costs.

One of the leaders supplying the companies with accessories for automation worldwide is German Conglomerate Company "Siemens". The company has been manufacturing specialized equipment introducing innovative original developments and advanced technologies for more than a century. The company offers unique automation systems the introduction of which enables centralized control of production processes. It helps to improve labour productivity and performance to a significant degree.

As a matter of practice, automation is classified into the following subtypes:

- Partial automation. Such automation is important wherein the equipment with automation has been initially installed. Partial automation controls only some manufacturing processes that are either super complex or transient.

- Complex automation. In case of such automation a separate workshop or production site operates in unison, like a single organism. Man’s function in this case is to control and operate the process.

- Complete automation. This type of automation is the supreme effective control of complex technical and production process. The main condition under which the arrangement of such automation is justified - is a complete production profitability down the line.

Siemens Conglomerate Company manufactures specialized equipment systems, the introduction of which naturally results in increase of production volumes and cutting of production costs with full preservation or improvement of the goods quality. The production area requires maximum flexibility and efficiency due to the rapid movement of technological progress. Untimely actions may lead to loss of competitiveness and top position of the companies. Automation of production processes by Siemens will help to avoid such problems and always to hold the first positions of manufacturers’ rating.

Trademark SIMATIC by Siemens specializes in production of complex automation systems. Using these systems it is easily possible to create systems of production control of any complexity, all these is possible on the basis of standard components. Systems SIMATIC by Siemens company are based on the following basic principles:

- Uniform methods of industrial communication.

- Uniform methods of data processing and storage.

- Uniform methods of equipment programming and diagnostic.

Complex systems of industrial automation SIMATIC by Siemens has earned popularity among the world's leading manufacturing companies by providing processes regularity, nullifying of manufacturing defects, efficient control of any production and it does not have any alternatives in actual fact.

Categories of equipment, included to SIMATIC system, are as follows:

- Microsystems SIEMENS LOGO. The category includes microcontrollers, universal logic modules, a variety of stabilized power sources. They provide performance, functionality and cost efficiency of production.

- Programmable controllers. This innovative invention allows to carry out automation of any process, it is characterized by high reliability performances and an excellent ability to adapt to a particular task.

- Fast digital control systems. They are designed to provide a high responsiveness of control and accuracy of calculations. They are widely used in control of speed and synchronous rotation, work of compensating and "robust" electrical shafts, dynamic and hydraulic actuators, regulation of tension and unwinding.

- Distribution peripheral systems. They are IO station used in distributed automatic control systems.

- PC-based automation by Siemens. A wide range of products based on advanced computer technologies. This category includes industrial PCs, printing devices, network cards and much more. Industrial computer equipment is a powerful and effective tool of engineering.

- Software. System developers of Siemens Company regularly improve software with a view to complete interaction of all automation systems providing the possibility of configuration, design and planning, as well as testing, adjustment, logging, central control and archiving of all data.

- Visual system. They enable creation of human-machine interface and are built in the systems of programmable controllers. These systems allow to set the unification with the controllers and to create a unified interface, ensure efficient operation of a network and have a direct connection to the controllers. It is a complex of displays, text bars and graphic panel, touchscreens and keypads.

- Industrial networks. Specialized network solutions by Siemens provide network data exchange according to the established international standards using global or local information networks. Communications in Siemens SIMATIC automation systems run through PROFIBUS-DP, AS-Interface and EIB networks.

- Industrial process control systems. The system has an extensive and flexible architecture that is fully adapted to solving of any production problems. It provides absolute security, reliability of cooperation in operation of the production facility.

For efficient operation the company needs to introduce the systems of industrial automation, equipment of Siemens company - is the most optimal solution. Automation systems by "Siemens" can be easily integrated, are capable to solve any production task. The benefits of automation are undeniable:

- the ability of analogue formation and control of any supercomplex process with arithmetic accuracy;

- the processes are open and transparent;

- standardization of processes with an ability of control from any point of the company.

Siemens Company has been practicing a packaged approach to solving of any problems, specialists are not just aware of the latest innovations in this field, but they themselves are engaged in innovative developments to improve efficiency and productivity. Constant credo of the company - is to ensure complete safety for human life and health, environmental friendliness and energy efficiency of resources consumed. All Siemens equipment is consistently of high quality, absolutely cost-effective, the variety range of equipment allows recreation of an individual automation system.